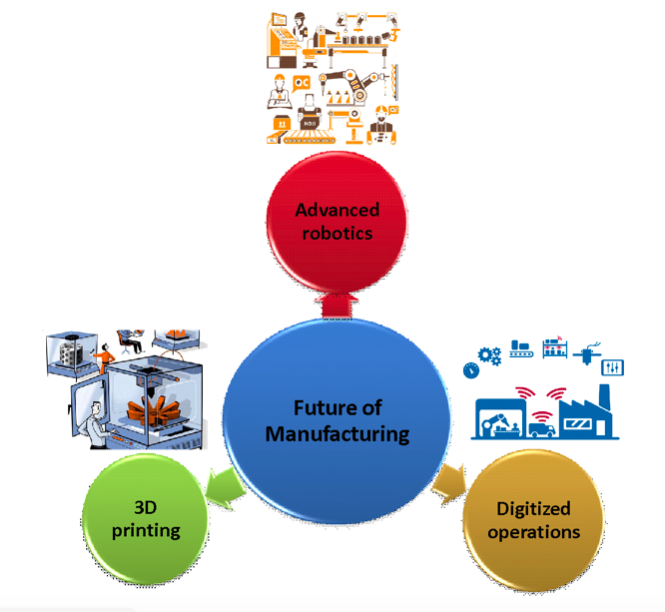

Many companies worldwide successfully combined automation, artificial intelligence and internet of things to achieve better quality and productivity. The various innovations in future manufacturing industries include 3D printing, advanced robotics, large scale factory digitisation, etc. According to McKinsey & Company report 2014, technology disruptions ahead for manufacturing are mainly:

• Advanced robotics

• 3D printing

• Digitised operations

Advanced robotics

Use of robots is increased by 50% since 2008. Robots can perform various tasks like manipulating parts, picking and packing products and robots can work side by side with humans also. As that happens, companies are looking for new manufacturing system and provide new roles to mechanical workers.

3D printing

Currently 3D printing share in manufacturing sector is very less (0.02 percent). However, this industry is hoping to grow to more than $8 billion by 2020. 3D printing opens possibility of more distributed production networks and radical customisation. It is expected these printers will not replace high-volume production such as die-casting and stamping. However, the industry can grow and will become service business like copy or print shop to manufacture items based on designs.

Digitised operations

3D printing automation and robotics will lead to digitisation of operations. Cloud computing, mobile communications and internet of things are beginning to combine advanced analytics to create threads of intelligent data.

Digital data can give digital DNA of parts including materials, equipment and time required to make them is increasingly available.

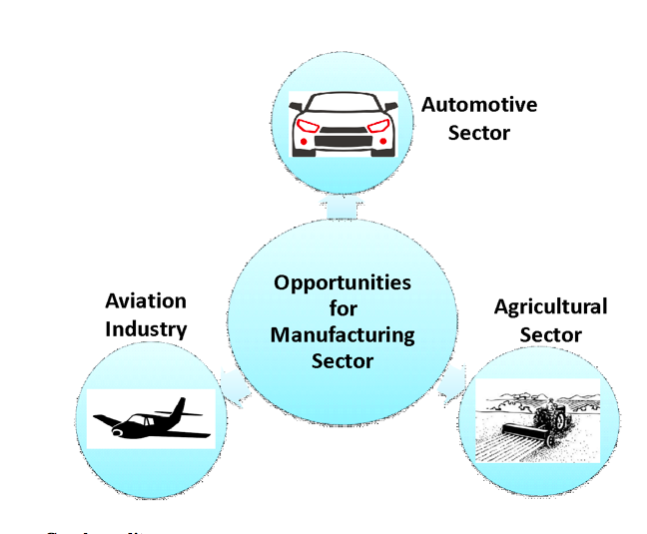

Opportunities for the manufacturing sector

In the next decade, Indian manufacturing industries has better chances of growth in “3A”

• Automobile sector,

• Aviation industry and

• Agricultural sector

According to IBEF sectors of manufacturing (Indian Brand Equity Foundation), Automobile experts growing by 14.5 per cement year – on – a year during FY (IBEF) and it is expected that automobile sector will reach Rs. 16.16 – 18.18 trillion by 2026. The various advantages for this sector include a rise in middle-class population and India could be the leader in mobility by 2030. Providing opportunities for electric and autonomous vehicles Government expecting automobile sector to attract US $ 8-10 billion in local and foreign investments by 2023.

The aviation industry in Indian is expected to become the third-largest aviation market around 2024. India is expecting an increase in operational airports to 190-200 by 2040. By 2028, this industry is expected to grow over US$ 2.4 billion.

The agricultural sector is also fast-growing for manufacturing allied industry like agrochemicals, production of farm equipment and continuous increase in consumption expenditure in farming. India is premising opportunities in storage facilities and agricultural automation.

A shift to smart manufacturing will save our corporations money and translate into greater profits, more jobs and healthier economies. As our machines move into a more complex age, so do our workers and products, symbiotically ushering in a new era of production.

666, Upper Indiranagar, Bibwewadi,

Pune, Maharashtra, INDIA - 411 037.

For Admission :- 91 - 7058432258 / 8793428634

For Admission :- Office Timing :-

Monday to Friday - 10am to 5 pm